DALI WJ-6 LHD underground loader is a compact automation-ready machine that has earned a reputation as a preferred loader in the industry. This combination of underground loader and underground hauler offers a 14-metric-ton capacity and excellent operator ergonomics as well as uninterrupted high productivity with low cost per loaded tonne.

|

Capacity

|

Operating Weight

|

| Standard bucket |

6m3(7.8 cubic yards) |

Total operating weight |

35000kg |

| Payload |

14T |

Front axle |

12980kg |

| Break out force |

224KN |

Rear axle |

21020kg |

| Traction |

287KN |

Weight, Loaded

|

| Climbing ability |

20° |

Total loaded weight |

49000kg |

|

Bucket Motion Time

|

Front axle |

27090kg |

| Raising time |

≤7.9s |

Rear axle |

21910kg |

| Dump time |

≤5.6s |

Dimension

|

| Lowering time |

≤3.7s |

Overall size |

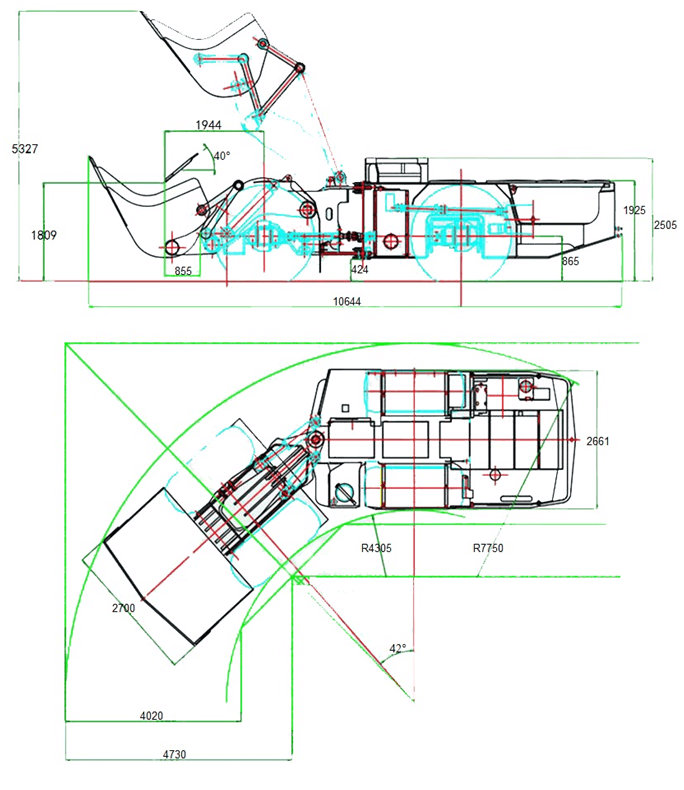

10644*2700*2505mm |

|

Speeds Forward&Reverse

|

Dumping height |

1809mm |

| 1st Gear |

0~5.2km/h |

Lift height |

5327mm |

| 2nd Gear |

0~11.3km/h |

Ground clearance |

424mm |

| 3rd Gear |

0~19.4km/h |

Unloading angle |

40° |

| 4th Gear |

0~28.7km/h |

|

|

|

Engine

|

| Diesel engine |

VOLVO TAD1350 |

Emission |

EURO III / Tier 3 |

| Output |

256kW/1900rpm |

Fuel Tank |

450L |

|

Power Train

|

| Torque Converter |

DANA C800 |

Axle |

DANA 53R |

| Transmission |

DANA R6000 |

Tire |

26.5-25 32 ply(L-5S) |

Main Features

>> Structure

The frames are articulated with 42° turning angle.

Ergonomics Canopy with side seat to provide broad bi-direction operation vision.

ROPS & FOPS certified cab.

Strong boom with two lifting cylinder.

>> Operation Comfort & Safety

Low vibration level in cab with suspension seat.

Hydraulic pilot control(JOYSTICK) to reduce the labor intensity of the driver.

Combination design of parking brake, working brake & emergency brake. Braking model is SAHR(spring applied, hydraulic release).

Rear Camera to provide good view for operation.

>> Early Warning & Maintenance

Automatic alarm system for oil temperature, oil pressure and electrical system.

Auto lubrication system.

>> Energy-saving & Environment Friendly

Catalytic purifier with silencer, which greatly reduces air and noise pollution in working tunnel.

Technical Specification

Dimension

Tramming:10644*2700*2505mm

Min Ground Clearance:424mm

Max Lift Height:5327mm

Max Dumping Height:1809mm

Max Unloading Angle:40°

Power Train

Engine

Diesel Engine:VOLVO TAD1350

Power:256kW/1900rpm

Emission:EURO III / Tier 3

Fuel Tank:450L

Purifier:Catalytic purifier with silencer

Torque Converter:DANA C8000

Transmission:DANA R6000

Axle

Model:DANA 53R

Type:Rigid planetary axle

Differential(Front):NO-SPIN

Differential(Rear):Standard

Wheel & Tire

Wheel Rim:22.00-25

Tire:6.5-25 32 ply(L-5S)

Operator’s Compartment

Canopy

ROPS & FOPS closed cab with air-conditioning.

Oil free operator’s compartment

Floor washable with water to reduce dust

Low frequency suspension seat

Dashboard & Displays

Critical warnings and alarms Displayed as warning lights

Instrument Panel Electric gauges

Instrument Panel Illuminated switches

Frame

Rear & Front Frame

High strength welded steel structure with optimized material thicknesses

Tanks Bolted & Welded

Bucket

Bias 450(anti-wear) Material

Type V shaped(reduce working resistance)

Hydraulics

Rexroth Filling pump for hydraulic oil

PARKER(USA) multi way valve

Rexroth hydraulic triplex pump(Gear Type) for working & steering(PARKER pump option)

Hydraulic Joystick(Pilot) control for working & steering with PARKER valve.

Oil cooler for hydraulic oil

550L Hydraulic oil tank capacity

Meter oil level

Hydraulically operated, center-point articulation, power steering with two double acting cylinders.

The oil flow from steering hydraulic pump is directed to bucket hydraulics when steering is not used. which can enlarge the working pressure.

Strong boom with two lift cylinders.

Two dump cylinder.

8μm LEEMIN Filter.

Brake

SAHR multi-disc wet brake at each wheel. Combination design of parking, working & emergency brake.

Electric

Alternator 100A / 28V

Batteries 2 x 12V

Starter 7.5kW / 24 V

Driving lights 4 in front 42W, LED lights, 4 in rear 24W, LED lights, 1 pc in the cable 24w, LED light

Others safety system

Engine Fire Suppression

Flashing beacon

Underground Scooptram

Underground mining scooptram is also known as underground mining LHD( Load Haul Dump), underground mining loader,underground mining LHD loader

A scooptram is similar to a front end loader with the exception of height / profile and bucket capacity. This low profile piece of heavy equipment is used in underground mining and it transports blasted or loose rock ore in an underground mine. A scoop or bogger will work the face and load ore cars which are then used to haul material that will ultimately be processed in a mill.

How scooptram works——The scooptram machine has a small distance from the ground, and the middle of the bucket relies on the expansion and contraction of the tipping cylinder to realize the scooptram’s bucket movement. Generally scooptram used in relatively flat places with little resistance. The following is a detailed description of the scooptram definition from the characteristic structure and use.

Typically, the model number will depict the capacity of the underground loader. For example, WJ-1 is a 1 metric tonne capacity underground loader.

The scooptram is used to load and dump ores in the underground mine tunnel. The working efficiency of scooptram has a great influence on the progress of the project. Here are some factors that have a greater impact on the working efficiency of scooptram.

The first is the operator’s proficiency. If the operator is not proficient to operate, it will not only affect the working efficiency, but also cause trouble in the usage. It will also cause great damage to the equipment and personnel, so the staff must have skilled experience before they can operate the machine.

The second factor is the daily maintenance before the operation of the machine, which requires routine inspection and lubrication before work to ensure that the equipment does not work with failure.

Features in scooptram definition

Scooptram has low requirements on driving roads

Scooptram has flexible operation and convenient operation

Scooptram has simple structure

Scooptram has high construction efficiency

Structure in scooptram definition

Scooptram is characterized in that the bucket with a shovel mechanism is composed of a bucket body, a sliding baffle, a rotating baffle, a shovel blade and a ground breaking knife; on both side walls of the bucket body, there is a pole shaft and a bucket body.

Wheel/traction beam/frame/hydraulic device/bucket with shovel mechanism/support structure and frame lifting adjustment mechanism

We produce 0.6 cubic meter (WJD-0.6), 1 cubic meter (WJD-1), 1.5 cubic meters (WJD-1.5), and 2 cubic meters (WJD-2) electric scooptrams, and 0.6 cubic meter (WJ-0.6), 1 cubic meter (WJ-1), 1.5 cubic meters (WJ-1.5), 2 cubic meters (WJ-2), 3 cubic meters (WJ-3), 4 cubic meters (WJ-4), 6 cubic meters (WJ-6), and 8 cubic meters (WJ-8) diesel scooptrams. The color, appearance, layout, logo, etc. of the scooptram can be customized according to customer needs.