WJ-2 2 CBM underground loader mining underground scooptram for sale

WJ-2 is a compact and lightweight Load Haul Dump (LHD) for underground narrow vein mining. It owns the best payload-to-own weight ratio in its class with the 2-cubic meter and 4-ton payload bucket. WJ-2 has an elongated arm, which increases the height of unloading so it can match bigger dumper.

Application:Non coal mine or ore

Bucket Size:2CBm(2.6 yards)

Payload:4000kg

Climbing Ability:25%

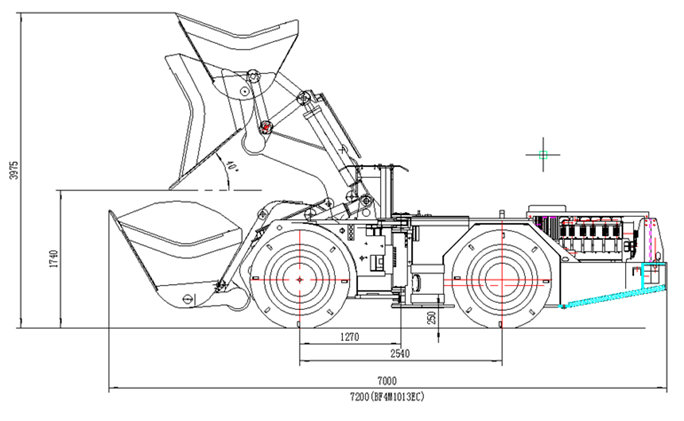

Overall Size:7000*1770*2050mm

Min. Ground Clearance:250mm

Max. Lift Height:3975mm

Max. Unloading Height:1880mm

Wheelbase:2540mm

Operation Weight:13500kg

Raising Time:≤6.3s

Dumping Time:≤4.0s

Lowering Time:≤3.6s

Engine:DEUTZ BF4M1013EC 115kw @ 2300rpm (Optional:DEUTZ F6L914 84kw/DEUTZ BF6L914 112kw/Cummins QSB4.5)

Fuel Tank Capacity:150L

Transmission:DANA RT32360

Torque Converter:DANA C272

Axle:METORIOR CY-2J-F/R (Optional:DANA 14D2149)

Tire:12.00-24 PR24 L-5S TT

Industry Standard

JB/T5500 China LHD loader standard

JB/T5501 methods of testing of LHD loader standard

JB8518 safety requirements of LHD loader standard

GB25518 safety requirements of LHD loader standard

Main Characteristic

Side Seated Operator for Bi-Directional Operation & Maximum Visibility and with MSHA – FOPS Certified Canopy

Spring Applied Hydraulically Released(SAHR), Fully Enclosed, Multiple Wet Discs at Each Wheel End

Articulated Hydraulic Power Steering, Pilot-Operated, Monostick Control

|

Capacity

|

Speed

|

| Bucket volume |

2m3(2.6 yards) |

1st Gear Speed |

0~4.4km/h |

| Payload |

4000kg |

2nd Gear Speed |

0~10.7km/h |

| Max Breakout Force |

85KN |

3rd Gear Speed |

0~17.4km/h |

| Max Traction |

104KN |

Working Circle

|

| Climbing Ability |

25° |

Boom Raising |

≤6.3s |

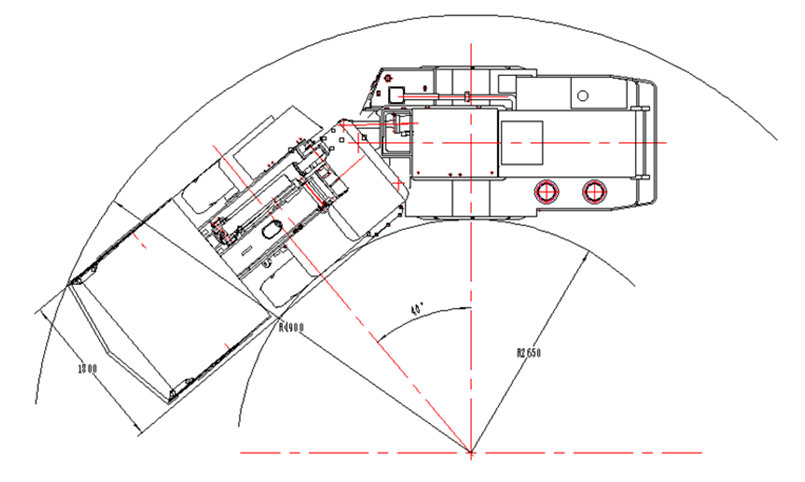

| Axle Oscillation |

±8° |

Dumping |

≤4.0s |

| Max. Unloading Angle |

40° |

Lowering |

≤3.6s |

|

Dimension

|

Weight, empty

|

| Overall Size |

7000*1770*2050mm |

Operation Weight |

13500kg |

| Min. Ground Clearance |

250mm |

Front Axle |

5100kg |

| Max. Lift Height |

3975mm |

Rear axle |

8400kg |

| Max. Unloading Height |

1880mm |

Weight, laden

|

| Wheelbase |

2540mm |

Front Axle |

10500kg |

|

Engine

|

Rear Axle |

7000kg |

| Brand |

DEUTZ(Germany) |

Torque Converter

|

| Model |

BF4M1013EC |

Brand |

DANA |

| Power |

115kw @ 2300rpm |

Model |

C272 |

| Emission norms |

EU II, US T2 |

Transmission

|

| Number of cylinders |

4 in line |

Brand |

DANA |

| Displacement |

4.8L |

Model |

RT32360 |

| Max. torque |

577 Nm @ 1400rpm |

Axle

|

| Fuel tank capacity |

150L |

Brand |

METORIOR |

| Engine optional |

DEUTZ F6L914 84kw |

Model |

CY-2J-F/R |

| DEUTZ BF6L914 112kw |

Axle Optional |

DANA 14D2149 |

| Purifier |

DOC+POC+silencer |

Tire |

12.00-24 PR24 L-5S TT |

Underground Scooptram

Underground mining scooptram is also known as underground mining LHD( Load Haul Dump), underground mining loader,underground mining LHD loader

A scooptram is similar to a front end loader with the exception of height / profile and bucket capacity. This low profile piece of heavy equipment is used in underground mining and it transports blasted or loose rock ore in an underground mine. A scoop or bogger will work the face and load ore cars which are then used to haul material that will ultimately be processed in a mill.

How scooptram works——The scooptram machine has a small distance from the ground, and the middle of the bucket relies on the expansion and contraction of the tipping cylinder to realize the scooptram’s bucket movement. Generally scooptram used in relatively flat places with little resistance. The following is a detailed description of the scooptram definition from the characteristic structure and use.

Typically, the model number will depict the capacity of the underground loader. For example, WJ-1 is a 1 metric tonne capacity underground loader.

The scooptram is used to load and dump ores in the underground mine tunnel. The working efficiency of scooptram has a great influence on the progress of the project. Here are some factors that have a greater impact on the working efficiency of scooptram.

The first is the operator’s proficiency. If the operator is not proficient to operate, it will not only affect the working efficiency, but also cause trouble in the usage. It will also cause great damage to the equipment and personnel, so the staff must have skilled experience before they can operate the machine.

The second factor is the daily maintenance before the operation of the machine, which requires routine inspection and lubrication before work to ensure that the equipment does not work with failure.

Features in scooptram definition

Scooptram has low requirements on driving roads

Scooptram has flexible operation and convenient operation

Scooptram has simple structure

Scooptram has high construction efficiency

Structure in scooptram definition

Scooptram is characterized in that the bucket with a shovel mechanism is composed of a bucket body, a sliding baffle, a rotating baffle, a shovel blade and a ground breaking knife; on both side walls of the bucket body, there is a pole shaft and a bucket body.

Wheel/traction beam/frame/hydraulic device/bucket with shovel mechanism/support structure and frame lifting adjustment mechanism

We produce 0.6 cubic meter (WJD-0.6), 1 cubic meter (WJD-1), 1.5 cubic meters (WJD-1.5), and 2 cubic meters (WJD-2) electric scooptrams, and 0.6 cubic meter (WJ-0.6), 1 cubic meter (WJ-1), 1.5 cubic meters (WJ-1.5), 2 cubic meters (WJ-2), 3 cubic meters (WJ-3), 4 cubic meters (WJ-4), 6 cubic meters (WJ-6), and 8 cubic meters (WJ-8) diesel scooptrams. The color, appearance, layout, logo, etc. of the scooptram can be customized according to customer needs.